Lubrication system for air compressor

Lubrication reduces the friction between the moving parts of compressor and expels the heat generated.

The bearing and the running gear of compressors are lubricated using suitable, lubricating oil.

The image you see is the cross section of a single cylinder viewed from the side.

The lubrication system of a compressor comprises of a crankcase sump, a pressure pump, a strainer, a filter and a cylinder lubricator.

The compressor crankcase contains the lubricating oil.

The level of lubricating oil in the crankcase is maintained up to the preset mark by replenishing oil as and when required.

The gear type lubricating oil pump connected to the free end of the crankshaft is driven by the crankshaft through gear trains, chains or v-belts.

The pump takes suction from the crankcase through a strainer and delivers the lubricating oil through a fine filter to the bearings.

A pressure regulating valve is provided on the delivery side, which maintains the lube oil pressure.

The oil flows from the bearing to the crankpin through the holes in the crankshaft journals.

From the crankpin, the oil then flows to the bottom end bearing of the connecting rod. through the connecting rod, the oil reaches the top end bearing.

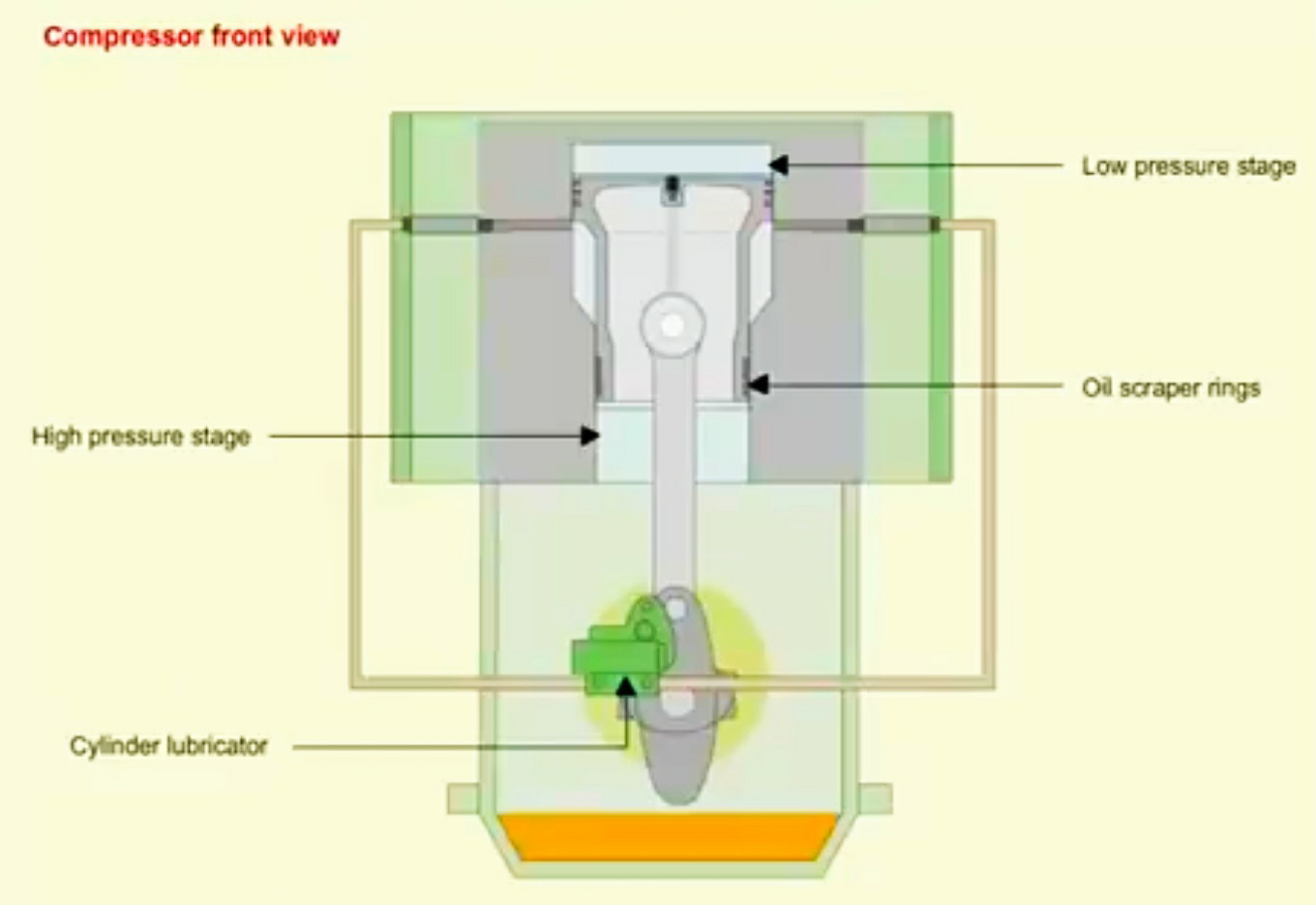

Now you are seeing the cross section of the cylinder viewed from the free end.

The bearing and the running gear of compressors are lubricated using suitable, lubricating oil.

The image you see is the cross section of a single cylinder viewed from the side.

The lubrication system of a compressor comprises of a crankcase sump, a pressure pump, a strainer, a filter and a cylinder lubricator.

The compressor crankcase contains the lubricating oil.

The level of lubricating oil in the crankcase is maintained up to the preset mark by replenishing oil as and when required.

The gear type lubricating oil pump connected to the free end of the crankshaft is driven by the crankshaft through gear trains, chains or v-belts.

The pump takes suction from the crankcase through a strainer and delivers the lubricating oil through a fine filter to the bearings.

A pressure regulating valve is provided on the delivery side, which maintains the lube oil pressure.

The oil flows from the bearing to the crankpin through the holes in the crankshaft journals.

From the crankpin, the oil then flows to the bottom end bearing of the connecting rod. through the connecting rod, the oil reaches the top end bearing.

Now you are seeing the cross section of the cylinder viewed from the free end.

No comments