Magnetic particle testing

- This method is used to detect surface and subsurface discontinuities in ferromagnetic substances. This is also used to test the weld works.

- The component which is to be tested is cleaned first.

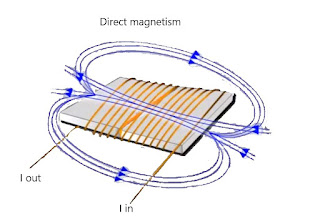

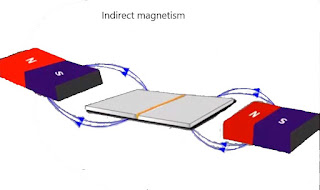

- After cleaning, the specimen can be magnetized either by direct magnetization or by indirect magnetization.

- Direct magnetization occurs when an electric current is passed directly through a specimen to produce a magnetic field.

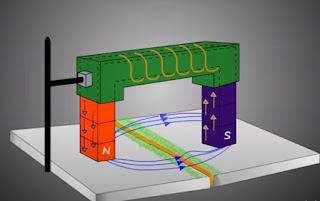

In indirect magnetization, magnetic field is applied by using a strong external magnetic field without passing current through the specimen.

- Indirect magnetization can be done by using permanent magnets or electromagnets.

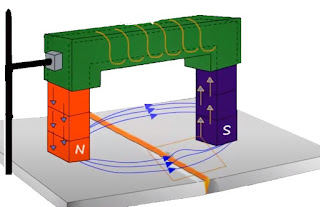

- Since magnetic fields in permanent magnet cannot be varied, electromagnets are preferred usually for testing.

- Electromagnet consists of a coil of wires through which current is supplied to produce a magnetic field.

- The amount of magnetic field produced depends on the amount of current passed through the coil.

- Magnetic flux created, is used to detect the flaws in the specimen.

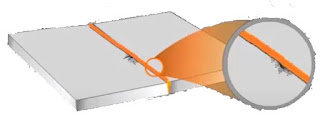

- This flux lines running along the surface will deviate from the path if it approaches a crack.

- Fine magnetic particles are applied to the surface of specimen for visible indication of cracks.

- These fine magnetic particles are attracted to the area of flux deviation, creating a visible indication of flaw.

- Simplicity of operation is the main advantage of magnetic particle testing.

- Major disadvantage of this method is that it is restricted to ferromagnetic substance, surface or near-surface flaws.

No comments