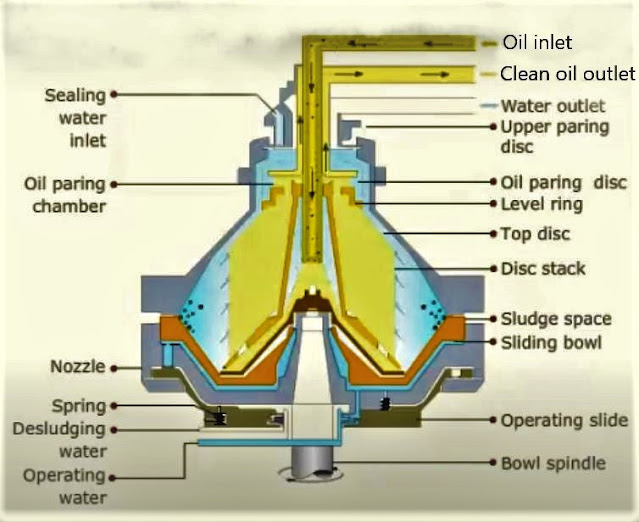

Closing of bowl

- After the purifier has attained its full rpm, the bowl closing water also called as the operating water is supplied at the bottom.

- Sliding bowl bottom is pressed upwards against a seal ring by the hydraulic force of the operating water.

Sealing water

- The sealing water is now supplied through the sealing water inlet.

- The supply of sealing water is continued until it comes out of the water outlet.

Dirty oil

- The dirty oil is supplied in to the bowl through the dirty oil inlet.

- Due to centrifugal force, the oil displaces the water and the sludge to the bowl periphery and rises upwards through the disc stack.

- The clean oil is then discharged through the clean oil outlet.

- Sludge and water particles accumulate at the bowl periphery and separated water is continuously discharged through the water outlet.

Desludging

- The sludge ports in the periphery of the bowl are covered by the sliding bowl bottom.

- For desludging, oil feed inlet to the purifier is stopped and the operating water is closed.

- The bowl opening water, also called the desludging water is supplied for a few seconds during which the water flows on from the top of the operating.

- The water force exceeds the spring force and pushes the operating slide downwards.

- The entire operating water is discharged through the nozzle.

- This causes the sliding bowl to move downwards, thereby opening the sludge ports.

- The sludge is discharged through sludge ports.

- The cycle is restarted and the operation continues.

No comments